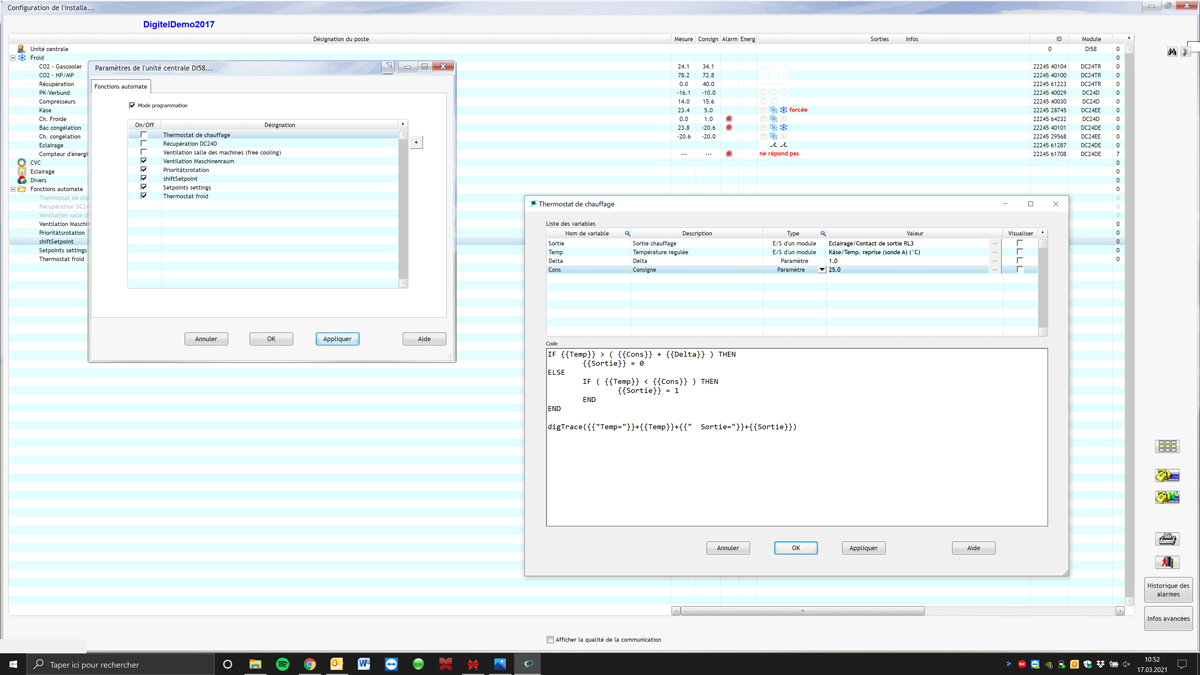

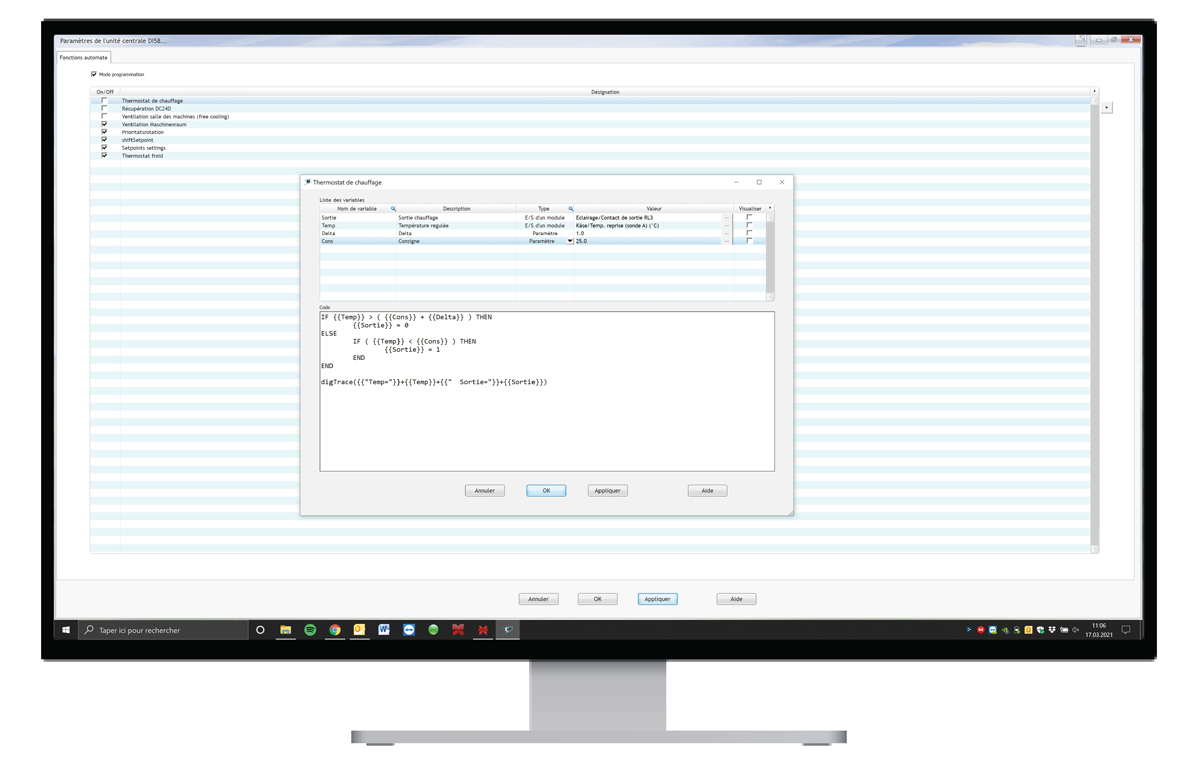

Customise the functions to your needs with the PLC

Digitel offers a unique, cutting-edge, integrated PLC function, with no other product on the market offering the same ease and flexibility of use.

In traditional PLCs, only the inputs and outputs of the PLC (which is a module added specifically for this purpose) can be used for the creation of new functions.

Digitel’s PLC can access all the controllers in the plant that are there to perform the usual functions (control of cooling units, compressors etc). It can modify their standard operation and use the free inputs and outputs to create new features.